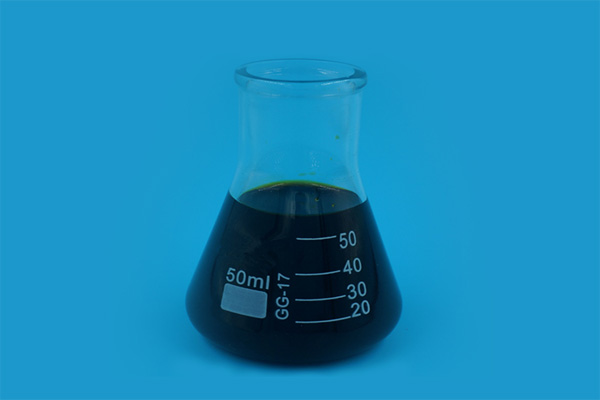

Description

In modern mining practices, froth flotation is a cornerstone technique employed in the recovery and beneficiation of sulfide ores. As one of the most efficient methods for separating valuable minerals like copper, lead, zinc, and nickel from their host rock, it relies heavily on specialized chemical reagents to optimize recovery rates and enhance process efficiency. Among these reagents, frothers play a critical role, and the introduction of CC 903 Frother has marked a significant advancement in sulfide ore flotation technology.

Understanding Frothers in Flotation

Froth flotation is achieved by selectively separating hydrophobic (water-repelling) particles from hydrophilic (water-attracting) ones in a slurry. Frothers are key reagents in this process, responsible for stabilizing the froth that forms at the surface of the flotation cell. A well-stabilized froth provides a medium for valuable mineral particles to attach and separate from the waste material or gangue.

Without an effective frother, the froth can collapse prematurely, resulting in low recovery rates and poor process efficiency. The challenge for frother technology lies in achieving the right balance — one that produces stable froths with optimal bubble formation while avoiding overfrothing, which can decrease mineral selectivity.

What Sets CC 903 Frother Apart?

CC 903 is a cutting-edge frother specifically developed for sulfide ores flotation. Unlike earlier-generation frothers, which could be limited in their performance under certain mineralogical and operational conditions, CC 903 offers superior versatility and reliability.

Here are some of the standout features of CC 903:

1. Enhanced Froth Stability

CC 903 provides excellent froth structure and stability, even under varying pH levels and strong agitation. This ensures that valuable sulfide minerals effectively attach to bubbles and are carried to the froth layer for separation. Its stability also reduces the risk of froth collapse, which can lead to suboptimal recovery rates.

2. Selective Bubble Formation

A major factor in frother performance is bubble size distribution. CC 903 has been carefully engineered to generate fine to medium-sized bubbles that promote selective attachment of sulfide particles while minimizing unwanted gangue material recovery. This improved selectivity translates to better concentrate grades in the flotation process.

3. Wide pH Range Applicability

The flotation of sulfide ores often requires basic or acidic conditions, depending on the ore characteristics and overall plant operation. CC 903 functions effectively across a broad pH range, making it highly adaptable to diverse operating environments.

4. Compatibility with Other Reagents

CC 903 is designed to work synergistically with other flotation reagents such as collectors, depressants, and modifiers. This compatibility ensures streamlined operations and consistent results across different ore types and processing parameters.

5. Cost-Effectiveness

The mining industry constantly seeks to optimize operational costs while improving efficiency. CC 903 delivers high performance at an economical dosage, making it an attractive choice for flotation circuits looking to boost profitability without compromising on quality.

Applications of CC 903 in Sulfide Ore Flotation

CC 903 has been successfully applied in the flotation of a variety of sulfide ores, including:

Copper Sulfides: It has demonstrated excellent recovery rates for chalcopyrite, bornite, and other copper-bearing minerals.

Lead-Zinc Ores: CC 903 enables effective separation in flotation circuits designed for galena and sphalerite recovery.

Nickel Sulfides: The frother improves the recovery of pentlandite and other nickel-based minerals, even in complex ore mineralogies.

Its robust performance has made CC 903 a preferred frother choice for mining operations with challenging ores that exhibit varying particle sizes, mineral compositions, and process water chemistries.

Sustainability and Environmental Benefits

As the mining industry places greater emphasis on sustainability, reagent manufacturers are under pressure to develop solutions that minimize environmental impact. CC 903 aligns with this vision, offering several eco-friendly advantages:

Biodegradability: CC 903 is formulated to degrade naturally over time, reducing its environmental footprint.

Low Toxicity: Its low toxicity profile ensures safer handling, storage, and disposal compared to many traditional frothers.

Reduction in Secondary Waste: The frother’s efficiency helps minimize the generation of tailings and leftover waste, making downstream waste management simpler and more cost-effective.

Conclusion

The introduction of CC 903 Frother represents a paradigm shift in sulfide ore flotation. Combining high efficacy, selectivity, and environmental compatibility, it delivers excellent flotation performance and economic benefits for mining companies seeking to optimize their operations. As the global demand for metals continues to grow, advanced frothers like CC 903 will play an increasingly vital role in meeting the industry’s needs in a cost-effective, sustainable, and environmentally responsible manner.

By bridging innovation and practicality, CC 903 stands poised to remain a frontrunner in frother technology, empowering the mining industry to achieve new heights in sulfide ore beneficiation.

Reviews

There are no reviews yet.