Description

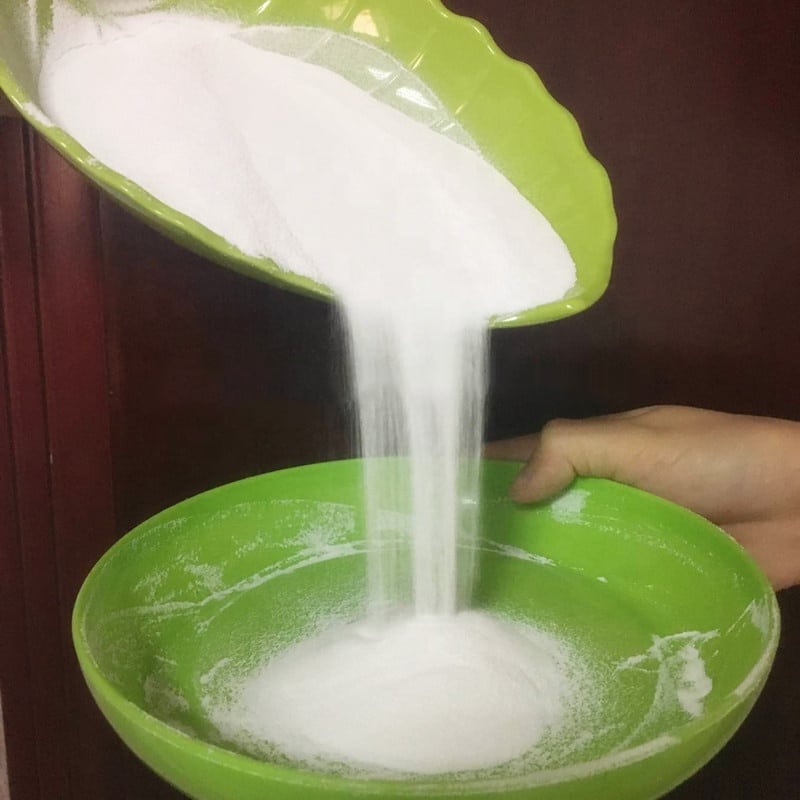

Low Viscocity Poly Vinyl Chloride: Flowing into New Applications

Polyvinyl chloride (PVC), a ubiquitous polymer, is known for its versatility, durability, and cost-effectiveness. However, standard PVC often presents processing challenges due to its relatively high viscosity. This is where low viscosity PVC comes into play, offering a more fluid alternative that opens up a wider range of applications and enhances manufacturing efficiency.

Understanding Viscosity

Viscosity, in simple terms, is a measure of a fluid’s resistance to flow. Think of honey versus water; honey has a higher viscosity, meaning it’s thicker and flows more slowly. In the world of polymers like PVC, high viscosity translates to difficulties during processing. It can require higher temperatures and pressures during extrusion, injection molding, and other manufacturing processes, potentially leading to increased energy consumption and reduced throughput.

Low Viscosity PVC: A Game Changer

Low Viscocity Poly Vinyl Chloride, as its name suggests, is formulated to have a lower resistance to flow than conventional PVC. This reduction in viscosity is often achieved through the careful selection of additives, plasticizers, and special polymerization techniques. By modifying the molecular structure and interactions within the polymer, manufacturers can significantly reduce its viscosity without compromising its desirable properties like chemical resistance, mechanical strength, and durability.

Key Advantages of Low Viscosity PVC:

Improved Processability: The primary advantage of low viscosity PVC is its enhanced processability. It flows more readily, allowing for faster molding cycles, easier injection into complex molds, and lower processing temperatures. This leads to:

Increased Production Efficiency: Faster cycle times mean more products can be produced in a given timeframe, boosting overall productivity.

Reduced Energy Consumption: Lower processing temperatures and pressures translate to lower energy requirements, contributing to cost savings and a smaller carbon footprint.

Enhanced Part Quality: The improved flow characteristics lead to better filling of molds, resulting in more uniform and higher quality finished products.

Wider Application Scope: Low viscosity PVC expands the application possibilities for the material by enabling processes that were difficult or impossible with standard PVC, such as:

Thin-Walled Products: The improved flow makes it easier to create thinner and more delicate parts like films, foils, and intricate components.

Complex Shapes: The ability to flow into complex molds means manufacturers can produce items with intricate designs.

Micro-molded Parts: Low viscosity PVC is suitable for micro-molding, a process used to create extremely small and precise plastic parts.

Reduced Additive Usage: In some cases, lower viscosity can reduce the need for high levels of plasticizers, which can sometimes compromise the physical properties of the material.

Potential for Cost Reduction: Efficiency gains and reduced energy consumption can contribute to lower manufacturing costs.

Applications of Low Viscosity PVC:

Low Viscocity Poly Vinyl Chloride is finding its way into a variety of applications, including:

Medical Devices: Tubing, connectors, and other components that require precise molding and thin walls.

Packaging: Films, blister packs, and rigid containers where improved flow and thinness are beneficial.

Automotive Components: Lightweight interior trim and small parts.

Construction: Flexible profiles and seals.

Electronics: Housings and connectors.

Toys and Novelties: Complex and intricately shaped playthings.

Conclusion:

Low Viscocity Poly Vinyl Chloride represents a significant advancement in the polymer industry. By addressing the processing challenges associated with standard PVC, it opens up new avenues for product design, manufacturing efficiency, and sustainability. Its enhanced flow characteristics, coupled with the inherent benefits of PVC, make it a compelling material choice for a growing range of applications. As research and development continue, we can expect to see even wider adoption of low viscosity PVC in the future, driven by the demand for higher performance, cost-effectiveness, and environmental responsibility. This innovation highlights the ongoing commitment to improving and adapting materials to meet the evolving needs of diverse industries.

Reviews

There are no reviews yet.