Description

In the world of mineral processing, chemical reagents play a pivotal role in enhancing the efficiency of mining operations. One such crucial chemical is sodium amyl xanthate (SAX), a widely used collector in the froth flotation process. This versatile compound is an essential component in mining operations, particularly in the extraction of sulfide ores, including copper, lead, zinc, and gold. Let’s take a closer look at what sodium amyl xanthate is, how it works, and why it remains indispensable to the mining industry.

What is SAX?

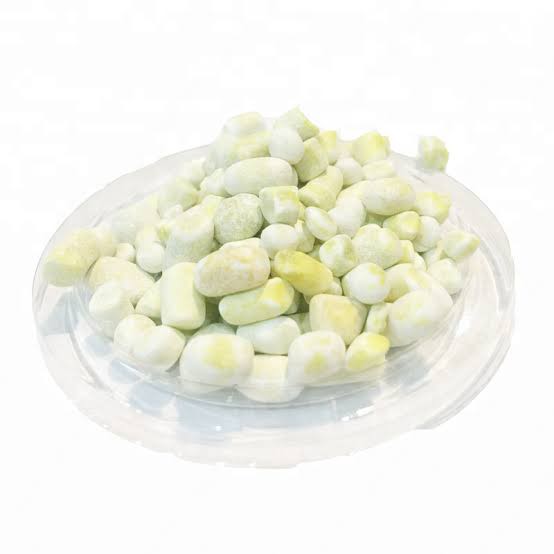

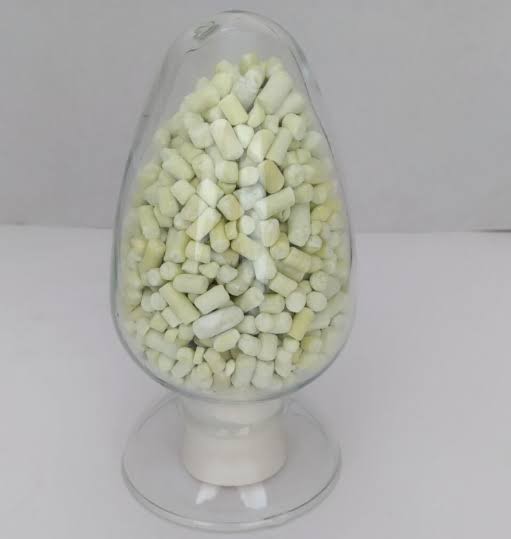

Sodium amyl xanthate (C5H11OCS2Na) is a pale yellow to greenish-yellow powdered or pellet-like compound that has a mildly pungent odor due to its sulfur content. It falls under the category of xanthates, a family of organosulfur compounds named after the Greek word “xanthos,” which means yellow. Xanthates are widely used in flotation processes as collectors—specialized chemicals that attach to the surface of mineral particles, rendering them hydrophobic (non-wettable) so they can be separated from unwanted material.

Sodium amyl xanthate is made by reacting carbon disulfide, sodium hydroxide, and amyl alcohol (pentanol). Its chemical structure allows it to bind effectively to the surfaces of sulfide mineral particles, making it exceptionally effective across a range of ore types.

Applications of Sodium Amyl Xanthate

The primary application of sodium amyl xanthate is in the mining industry. Here’s a closer look at its roles:

1. Froth Flotation Process

Sodium amyl xanthate is a powerful collector that plays an integral role in the froth flotation process, a method used to separate valuable minerals from ores. During flotation, finely ground ore is mixed with water to form a slurry. Reagents like sodium amyl xanthate attach to the surfaces of sulfide minerals, imparting hydrophobic properties to them. Air bubbles are introduced into the slurry, and the hydrophobic mineral particles adhere to the bubbles, rising to the surface and forming a froth that can be collected. The non-mineralized gangue material remains at the bottom and is discarded as tailings.

Sodium amyl xanthate is particularly effective with sulfide minerals such as:

Copper sulfides (e.g., chalcopyrite)

Lead sulfides (e.g., galena)

Zinc sulfides (e.g., sphalerite)

Gold-bearing sulfide ores

2. Selectivity in Mineral Separation

Sodium amyl xanthate provides a high degree of selectivity, enabling the separation of different sulfide minerals within the same ore. Adjusting the concentration of SAX and other reagents in the flotation process can help optimize recovery rates and improve ore beneficiation.

3. Gold Extractive Metallurgy

In addition to sulfide ores, sodium amyl xanthate is also used in the processing of gold-bearing ores. It enhances the recovery of precious metals by efficiently separating sulfides that carry valuable gold particles. This makes SAX an integral player in the gold mining industry.

Advantages of SAX

The wide use of sodium amyl xanthate in mineral beneficiation is mainly due to its effectiveness and adaptability. Here are some of its key advantages:

High Collecting Power: SAX is a strong collector for sulfide ores and works efficiently, even with challenging ore types.

Improved Recovery Rates: Its chemical properties ensure high recovery of valuable minerals from the ore, reducing waste and optimizing resource utilization.

Cost-Effectiveness: Sodium amyl xanthate is produced on a large scale, making it an economical choice for mining operations.

Precautions and Environmental Concerns

While sodium amyl xanthate’s role in mineral beneficiation is unquestionable, it is important to handle this compound with care. Being a chemical reagent, SAX poses certain risks:

Reactivity: SAX is highly reactive with acids, releasing carbon disulfide, a toxic and flammable gas. Proper storage and handling procedures are critical.

Toxicity: SAX can be toxic if ingested or inhaled and may cause skin or eye irritation. Strict safety measures, including the use of personal protective equipment (PPE), must be implemented during handling.

Environmental Impact: Depending on the mining operation, xanthates may be released into the environment through tailings. Mining companies are responsible for ensuring that disposal practices comply with environmental regulatory requirements and that effluent treatment processes mitigate any potential ecological damage.

Sustainability concerns have also encouraged the search for alternatives. Modern research is focused on the development of biodegradable, environmentally friendly substitutes for traditional xanthates, but sodium amyl xanthate remains the industry standard due to its proven effectiveness and efficiency.

Conclusion

SAX continues to be a cornerstone of froth flotation processes in mining, facilitating the extraction of valuable metals and minerals necessary for modern industries. Its unique chemical properties, cost-effectiveness, and reliability make it an indispensable tool for mineral processing plants around the globe.

However, as industries move toward more sustainable and environmentally conscious practices, ongoing research into greener alternatives and improved handling techniques will ensure the responsible use of this chemical. For now, SAX remains a trusted ally in the pursuit of efficient and economic mining operations.

Reviews

There are no reviews yet.